DAKEN FCG Refractory Glazes

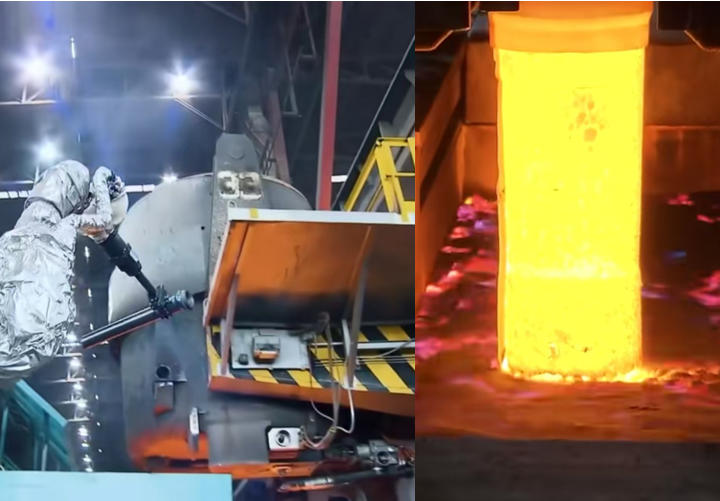

The continuous casting process in modern steel manufacturing demands high-performance refractory products for the flow control of molten steel. Daken FCG refractory glazes helps to protect these refractories during both the pre-heat and casting phases. Daken FCG refractory glazes are specially designed for the carbon contained flow control refractories, when Daken FCG refractory glaze coating is applied to the surface of the carbon contained refractories and dried, it will first form a dense protective layer, as the temperature of kiln rises to the range of 700 to 900°C in firing process, the glaze coating starts to melt, transform into a continuous, smooth and pore-less glassy film. This refractory glaze layer could completely isolates the oxygen from the carbon and graphite inside of the refractories product body, which provides a long-lasting protection for the carbon contained refractories products at high temperatures.

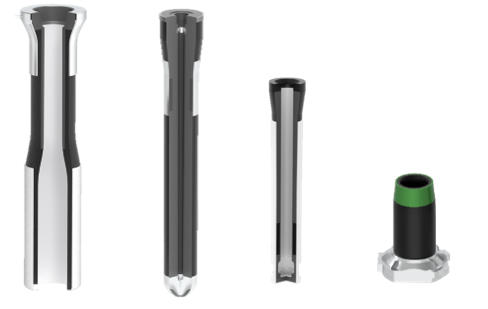

Daken FCG dry refractory glaze powder, could be mixed with water and binder, the fired glaze layer could provide excellent protection for ladle shrouds (LS), stoppers, and submerged nozzle(SEN) refractories product during preheat and continuous casting process in high temperature up to 1300 ℃. Daken FCG refractory glaze serve as a thermal barrier between the molten steel and the flow control product body, help refractory materials withstand physical stresses and prevent erosion and oxidation in the extreme heat being used during continuous casting process.

Application method:

Coating for graphite contained refractories by dipping, flooding or spray.

Storage condition:

Store under dry conditions, avoid moisture absorption and extreme temperature fluctuations.